Load All System

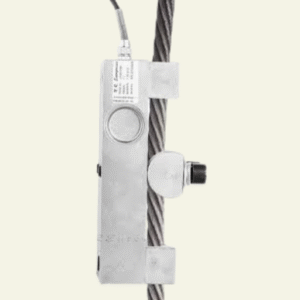

A wire rope load cell system is a specialized force measurement solution designed to monitor tension or load in wire ropes (also called steel wire cables) used in cranes, hoists, elevators, suspension bridges, mooring systems, and other lifting or tensioning applications. Unlike traditional load cells that measure compression or tension in a single direction, wire rope load cells are clamped or integrated directly onto the wire rope to measure real-time tensile forces without cutting or terminating the rope.

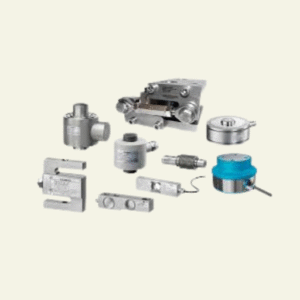

Key Components of a Wire Rope Load Cell System

Component

Description

1. Clamp-on Load Sensor (Load Pin or Saddle-Type)

The core sensing element. It clamps around the wire rope and uses strain gauges to detect deformation caused by tension.

2. Wire Rope

The load-bearing cable (6×19, 6×36, rotation-resistant, etc.). Diameter typically 8–60 mm.

3. Signal Conditioning Unit

Amplifies and converts the sensor’s mV signal into 4–20 mA, 0–10 V, or digital output (RS485, CAN, Modbus).

4. Display/Indicator

Local or remote digital display showing real-time load in kg, tons, or kN.

5. Data Logger / PLC Integration

For overload alarms, data recording, and integration with SCADA or crane control systems.

6. Overload Protection Relay

Triggers alarms or stops operation if safe working load (SWL) is exceeded.

Types of Wire Rope Load Cells

Mechanism

Best For

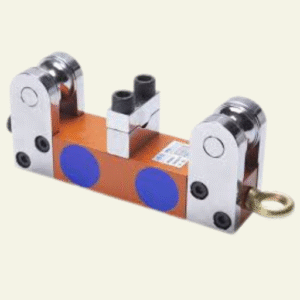

Clamp-on Saddle Type

Two half-shells clamp around rope; strain gauges on saddle

Easy retrofit, non-intrusive

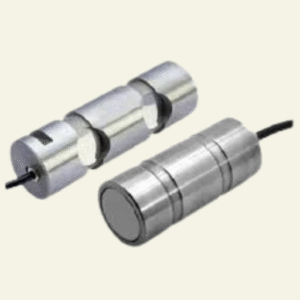

Load Pin (Sheave Pin)

Replaces existing pulley pin with instrumented pin

High accuracy, permanent install

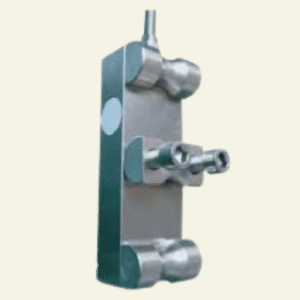

Running Line Tensiometer

Rope passes through three pulleys; middle pulley measures force

Dynamic lines, winches

Dead-End Socket Sensor

Sensor at rope termination (socket or wedge)

Fixed-end applications

How It Works (Clamp-on Type Example)

The load cell is clamped around the live section of the wire rope.

As tension increases, the rope slightly deforms the sensor body.

Bonded strain gauges in a Wheatstone bridge configuration detect micro-strains.

Output: ~2 mV/V at full load → amplified to standard signal.

System displays actual load and can trigger overload cutoff.

Accuracy: ±1% to ±2% of full scale (FS)

Capacity Range: 1 ton to 200+ tons per rope

Rope Diameter Compatibility: 8 mm to 90 mm (custom available)

Advantages

✅ Benefit

Description

Non-intrusive

No need to cut or replace rope

Easy Installation

10–15 minutes with basic tools

Real-time Monitoring

Prevents overload, extends rope life

Safety Compliance

Meets ISO 4309, ASME B30, LOLER, EN 13889

Retrofit Friendly

Ideal for older cranes without built-in load sensing

Typical Applications

Industry

Use Case

Cranes

Tower, mobile, overhead cranes (anti-two-block, SWL monitoring)

Elevators

Rope tension balancing, overload detection

Marine

Anchor winches, mooring lines, davit cranes

Mining

Hoist ropes, draglines

Construction

Pile driving, material lifts

Entertainment

Stage rigging, flying systems

Installation Tips (Clamp-on Type)

Select correct model for rope diameter and construction.

Clean rope surface (remove grease, rust).

Position sensor on straight section (avoid bends or sheaves).

Torque clamp bolts evenly to manufacturer specs.

Calibrate using known test weight or shunt calibration.

Route cable away from moving parts.

Warning: Never install on rotating or spinning rope sections.

Standards & Safety Factors

Parameter

Typical Value

Safety Factor (SF)

5:1 to 10:1 (depending on application)

Proof Load

200% of rated capacity

IP Rating

IP67/IP68 (waterproof, dustproof)

Temperature Range

-20°C to +80°C (standard), -40°C to +120°C (optional)

Example System Specification (10-ton Crane Rope)

Item

Spec

Rope Diameter

16 mm

Load Cell Type

Clamp-on saddle

Capacity

0–15 tons

Output

4–20 mA

Accuracy

±1% FS

Display

Digital panel meter with relay output

Alarm Setpoint

90% SWL (9 tons) → Warning110% SWL → Shutdown

Leading Manufacturers (India & Global)

Brand

Country

Notes

Eilon Engineering (Ron Crane Scales)

Israel

High accuracy, wireless options

Straightpoint (Crosby)

UK

Radiolink plus, Bluetooth app

Magtrol

Switzerland

High-end systems

Sensy

Belgium

ATEX versions for hazardous areas

Load Cell Systems

USA

Custom clamp-on designs

Inland Industrial (India)

India

Cost-effective, IS-certified

Sushma Industries (India)

India

OEM supplier, good support

Cost Estimate (India, 2025)

Capacity

Type

Approx. Price (INR)

5–10 tons

Clamp-on

₹45,000 – ₹75,000

20–50 tons

Load pin

₹1,20,000 – ₹2,50,000

Full System (with display + relay)

—

₹80,000 – ₹3,50,000

Prices vary by brand, certification, and wireless features.

Maintenance & Calibration

Visual inspection: Monthly (check clamps, cable damage)

Zero check: Before each shift

Full calibration: Annually or after overload event

Use certified test weights or shunt calibration

Need a Custom Solution?

If you’re in India, local suppliers like Sushma, Load Master, or Interface Force can provide:

On-site installation

Integration with PLC/HMI

Wireless data transmission

NABL traceable calibration

Want a datasheet or supplier recommendation for your specific rope diameter and crane type?

Reply with:

Rope diameter (mm)

Max load (tons)

Crane type (tower/mobile/overhead)

Output needed (analog/digital/wireless)

I’ll give you a ready-to-buy system config.