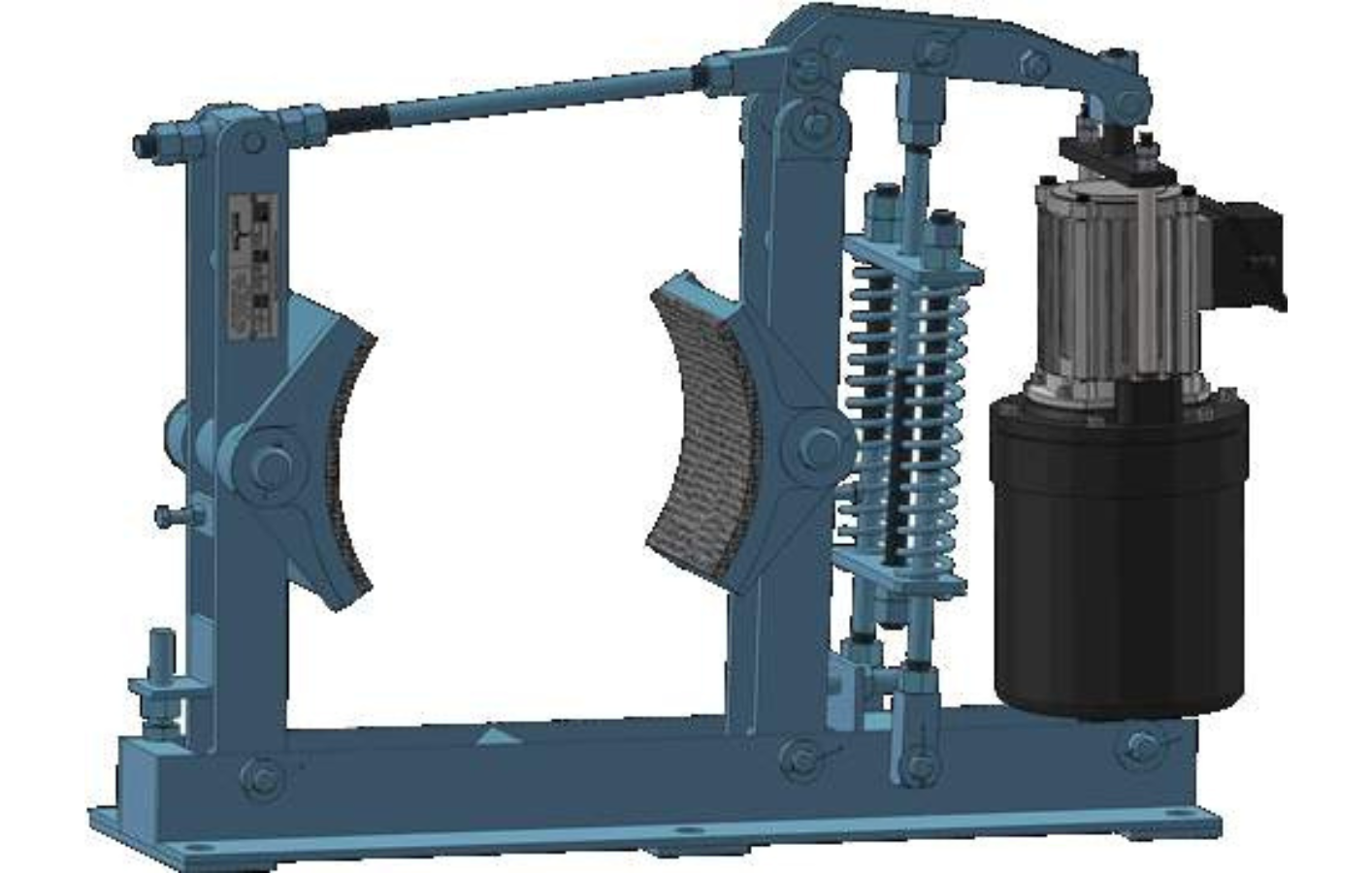

A Thruster Brake is an essential component in cranes and industrial lifting equipment, designed to control motion and provide precise braking force. It ensures smooth operation, safety, and reliability during lifting, lowering, and load positioning tasks. Thruster brakes are widely used in EOT cranes, gantry cranes, hoists, and other material handling systems where controlled stopping and load holding are critical..

Key Features

- Precision Braking: Provides smooth and accurate control over crane motion.

- High Durability: Built to withstand heavy industrial usage and continuous operations.

- Fail-Safe Design: Automatically applies the brake in case of power failure (depending on design).

- Easy Maintenance: Designed with minimal wear-and-tear parts for easier servicing.

- Temperature & Load Resistant: Operates reliably under high load and industrial conditions.

How It Works

The Thruster Brake operates using electro-hydraulic or electro-mechanical principles.

-

When the brake is engaged, a piston or actuator generates a force that applies pressure on the brake shoes or disc, slowing down or stopping the crane.

-

When the brake is released, hydraulic or spring mechanisms allow the crane to move smoothly.

-

This controlled braking mechanism prevents jerks, overshoots, and mechanical stress, ensuring safe handling of heavy loads.